Modeling Complex Transmission and Reflection

Complex materials and geometry can be used in daylighting apertures to modulate the amount and direction of light passage, as shading devices, or as exterior cladding. With these materials, the nature of the transmission and / or reflection varies dramatically depending on the relationship of the incoming angle of sun to the orientation of the material and the viewing angle of an observer.

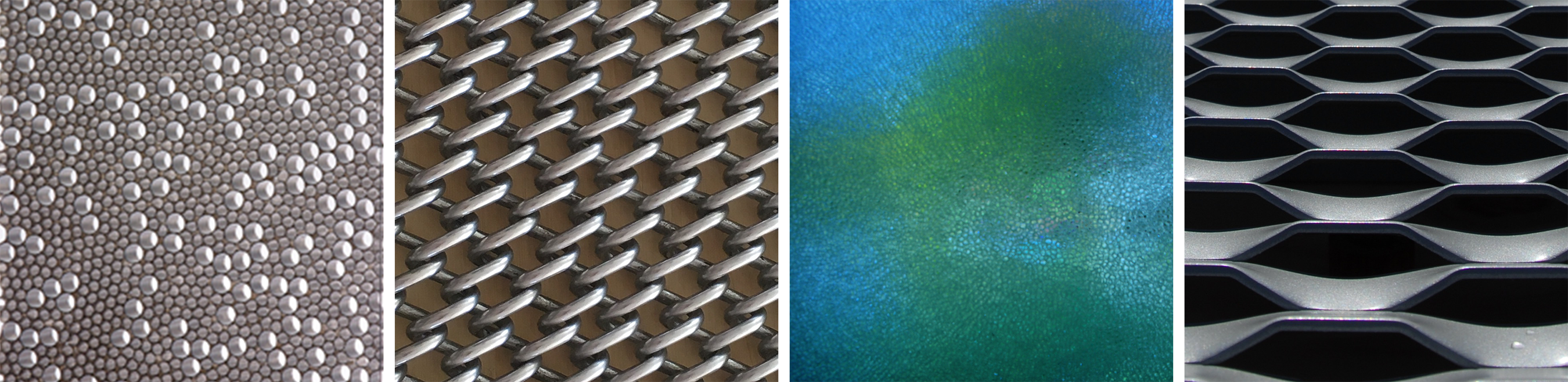

Range of Complex materials used in daylighting and visual comfort simulations that required in-house BSDF generation

A great example of this angularly dependent transmission and reflection would be blinds with curved slats and a gloss finish. You can imagine that certain sun angles would be blocked by the blinds while other sun angles would slip through between the slats. With a gloss finish, bright reflections could be visible for some sun angles but not others and how both the sun entry (transmission) and bright reflections are experienced changes with the observer’s relationship to the blinds. All of these transmission and reflection relationships can be seen in the photo below.

In the diagram below to the right, specular (direct) transmission and reflection and diffusing or scattering transmission and reflection are all represented for a single incident angle.

Low angle sun entering through exterior blinds with bright reflections visible (left). BSDF diagram – By Jurohi, CC BY-SA (right).

For simple systems in small numbers, such as blinds for a single room, digitally modeling the actual geometry can be an option for analysis. For glazing products, some manufacturers provide a digital file that includes all of these angular relationships as a BSDF – Bidirectional Scattering Distribution Function. For most materials, this information is not available as the manufacturer has not had the product measured in a lab. When this is the case, we make these BSDF files in house for our advanced simulation.

When generating these BSDF files for use in our simulations and analyses, there are several considerations that are always present – some of which also apply when using manufacturer supplied BSDFs.

Resolution matters, the finer grained the measurement the better it will represent the actual product but at the cost of human and machine time. Time is spent during the generation of the BSDF files and when the files are used in simulation. The coarser the resolution of the function, the easier to generate and use but at the cost of accuracy. The questions being asked in our varied analyses will determine what resolution we may need. Even the highest resolution file will still smooth out or miss very peaky behavior such as pinpoint reflections. This can be acceptable for some uses cases but not for others.

Below, the manufacturer of a complex glazing system with highly reflective integral shading was able to provide both variable high resolution and low resolution BSDF files. These were used in a multitude of daylighting and visual comfort simulations during the design phase, however an actual project sample was also measured for verification of the simulation files AND, more importantly, to quantify what the simulation materials could not represent – the peak reflections and the “texture” of the material.

After the project was built, extensive site measurements were conducted. These post-completion calibrations are crucial for our ability to understand the accuracy as well as the potential blind spots present in our simulation methods.

BSDF in simulation. Peak reflections are spread over an angular “patch” which can under or over estimate the impact.

Site photographs of the installed product. Peak reflections are brighter than simulated but occupy a smaller area. Note that falsecolor scales are not the same across all images.

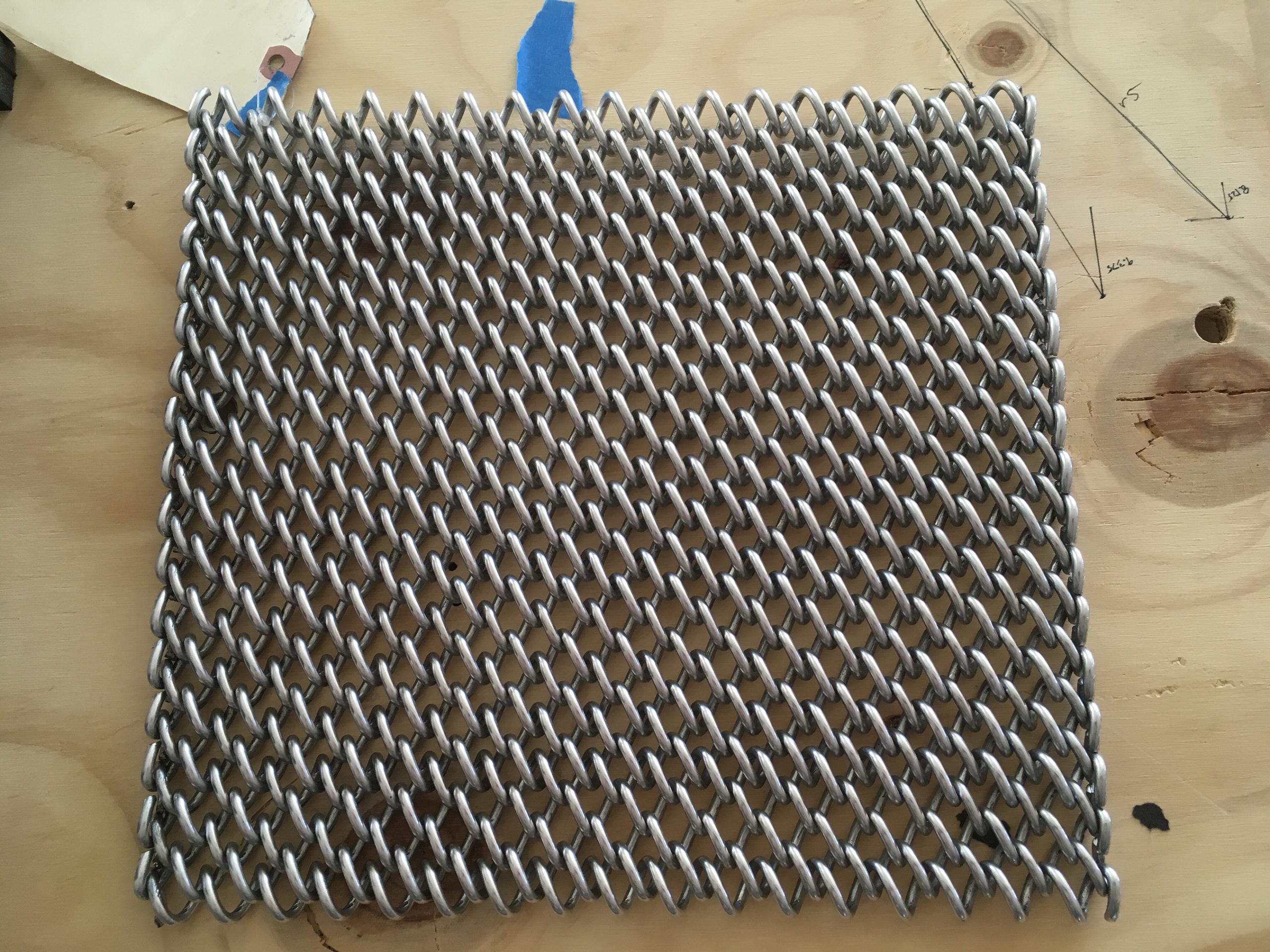

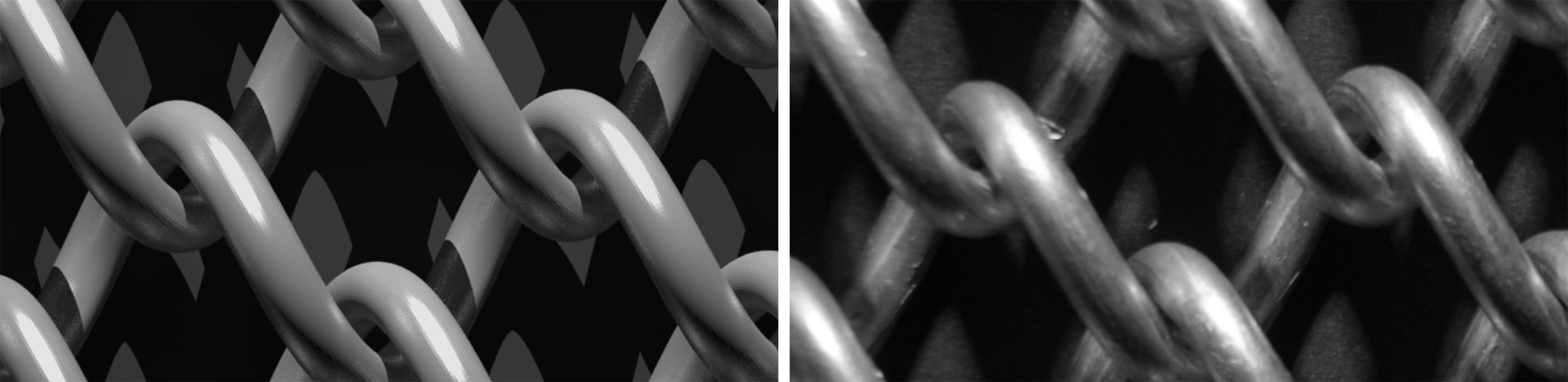

Generating a BSDF from a material sample requires extensive measurements in a lab environment with a Goniophotometer which can cost thousands of dollars and have a very long lead time. This is only a possibility for certain materials such as diffusing glass or shade fabric. It is not a possibility for materials like coiled metal mesh – see below. In those cases a digital twin that is geometrically identical to the physical product with accurate finish properties can be fed into a computer program to generate BSDF files. Low resolution files take minutes to hours to generate while the highest resolution files can take upwards of multiple days.

Digital Twin (left) and physical sample (right).

For one of our projects, a stainless steel coiled metal mesh from a fence manufacturer will be used as expansive shading canopies. The canopies provide both shelter from the sun as shading elements and a space for visual transition between the bright exterior and lower light levels of the interior. The shading performance and light transmission of the mesh are angularly dependent due to the geometry of the material.

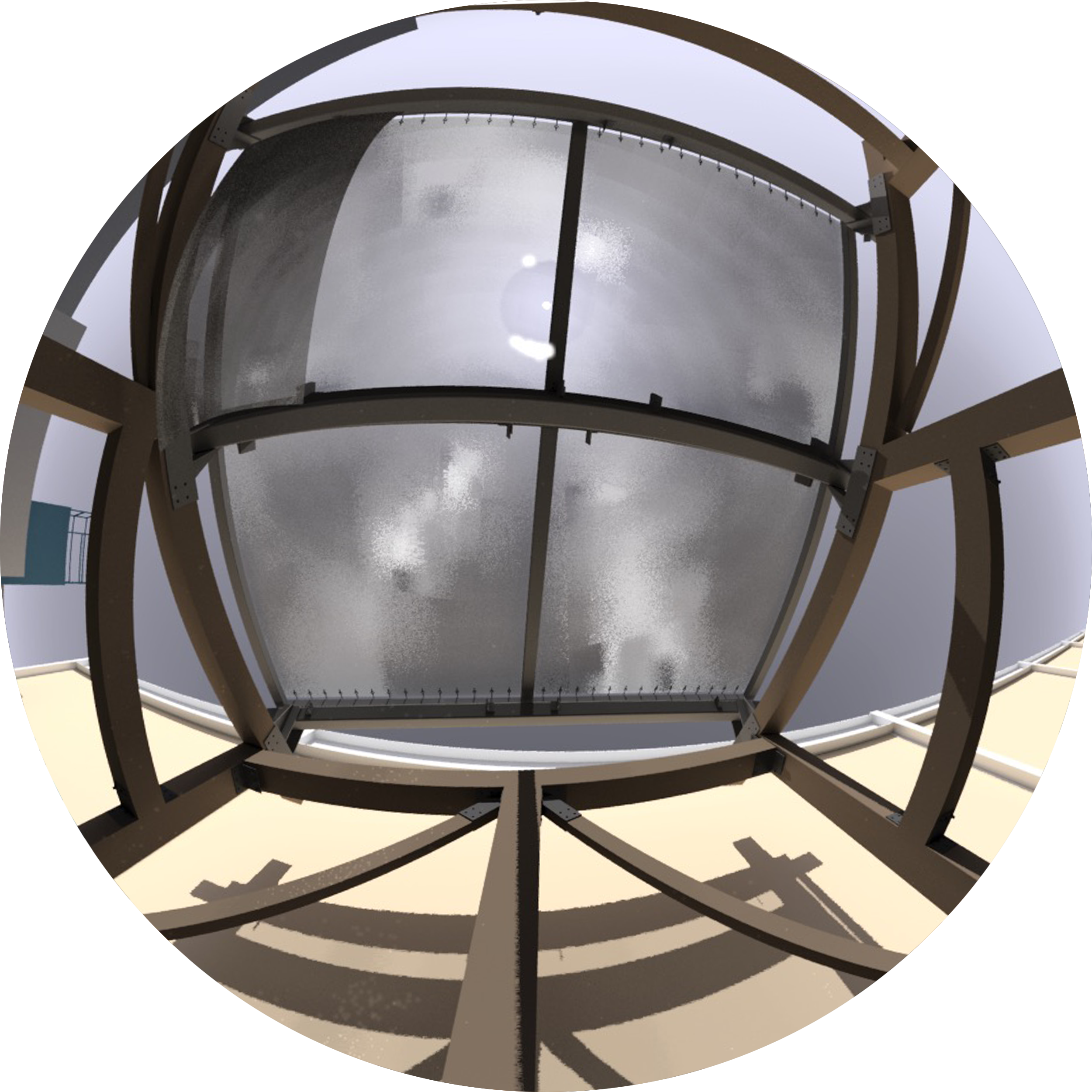

Simulation using generated BSDF of coiled metal mesh.

Photograph of physical mock up.

In addition to the angular transmission, reflections from the exterior of the canopies were also an area of analysis. We calibrated our digital twin to a physical sample of the material to generate the BSDF and then further tuned our generated BSDF as applied on our digital model to site measurements taken of a mockup.

Once fully calibrated, our BSDF could be applied to the whole building model for predictive reflection analysis.

Simulations with BSDF (left), photograph of mock up (center), BSDF applied to full building model (right).

Diffusing assemblies, such as glazing with applied films, sandblasting or acid etching, diffusing PVB interlayers and frit will also have complex and angularly dependent transmission and scattering. This type of assembly is something that can be measured by a Goniophotometer or generated in-house.

Various types of diffusing glazing.

Simulations using multi-layered diffusing BSDF assemblies. One is more diffusing (left) providing more uniform lighting conditions throughout the space, the other is more directional (right) providing dynamism with subtle changes in the light distribution as the sun moves through the sky.

Developing our own in-house workflow for generating BSDF files allowed us to test multiple mesh options, including variations in coil gauge, panel tension, metal selection and finishes and even dirt depreciation on the project with the mesh shading canopies. For the project above with the diffusing assemblies, we tested a matrix of glass options at both the upper skylight and the lower laylight, tuning the glass selection to achieve the desired interior lighting quantity and quality.

Rather than sending samples to a lab, waiting for results, and then completing a limited set of simulations, we use our models and our BSDF capabilities to assist in the material selection and design parameters to achieve the desired performance.

This expertise is applied directly to many of our services, from daylighting and visual comfort to electric lighting and building scale reflection analysis.

• Predict and evaluate illumination levels and light distribution

• Predict and analyze luminance gradients and glare potential

• Analyze thermal and energy use implications of daylighting design

• Design and evaluate daylighting to exhibition and curatorial performance criteria

• Predict energy savings from daylight harvesting

• Coordinate daylighting and electrical lighting design

• Post-occupancy HDRI analysis of luminance and visual comfort

• Specify luminaires, sources and layouts for electrical lighting

• Provide accurate renderings of lighting for evaluation

• Provide illumination levels for design evaluation as well as code requirements

• Provide lighting controls narrative and diagrams

• Arrange desk-top, lighting lab and/or in-situ mockups as appropriate to the project

• Provide aiming and lighting control observation

• Design custom fixtures

• Provide LEED credit documentation for lighting credits

• Analyze visual performance of glazing alternatives

• Evaluate advanced glazing applications, including light redirecting glass and internal shading systems

• Predict and evaluate thermal performance of curtain wall systems

• Predict occupant comfort conditions for curtain wall alternatives

• Identify and coordinate value engineering tradeoffs for integrated high-performance facades

• Analyze site conditions for solar access and shade potential

• Design sun control and glare control alternatives for local skies and climate conditions

• Evaluate shade alternatives for visual and thermal comfort

• Characterize reflections to understand temporal and spatial patterns

• Use calibrated simulations of solar radiation to quantify intensity and distribution

• Design and evaluate mitigation alternatives

• Week-long workshops focused on design of zero-energy, zero-carbon for practicing architects

• Teaching half-day or single-day workshops on focused topics such as low-energy lighting design, the use of HDRI in evaluating visual comfort

• Using hands-on sensing devices to understand and internalize the metrics used in zero-energy design

• Using current project form an architect’s practice to develop design alternatives and quantify the performance

While many of our tools and workflows are proprietary, we regularly collaborate with research and industry partners regarding BSDFs; from standards for measurement and file generation, to best practices for use in advanced simulation.

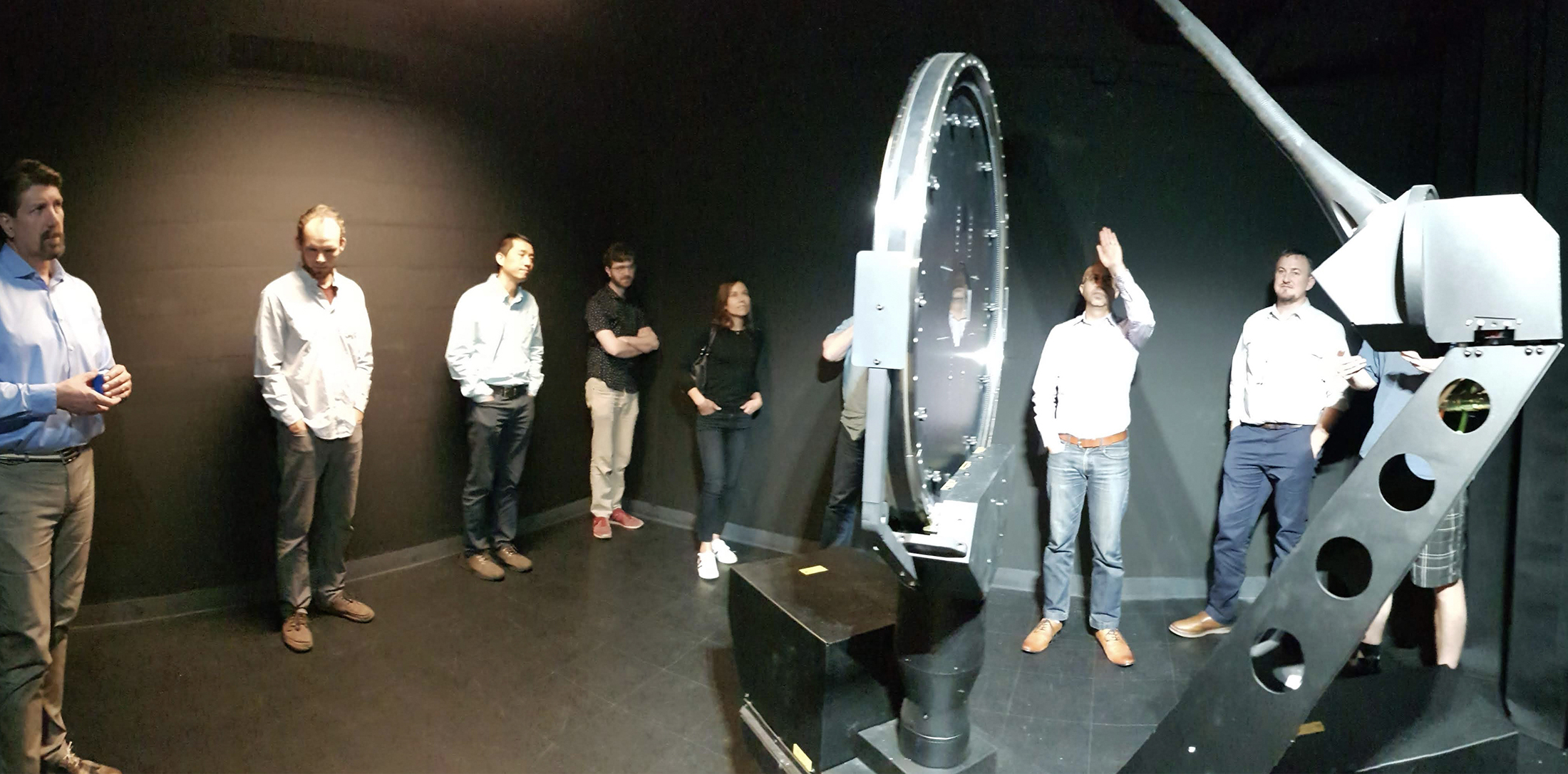

Touring LBNL’s goniophotometer during the 2019 BSDF workshop, photo credit Geisler-Moroder.

2022 Radiance Workshop Toronto group photo, photo credit Ward.